How it works?

Printing is achieved by placing a thermal ribbon between a heated printhead and the substrate to be marked. With the three items in contact, the printhead is moved over the length of both the ribbon and the substrate. Heat from the printhead is passed through the ribbon, causing ink to melt and be released from its underside. The ink adheres to the substrate and then cools rapidly, resulting in a permanent print.

Thermal transfer overprinters can operate in two modes depending upon how the printhead is moved relative to the ribbon and substrate. These are intermittent and continuous modes.

All Domino's printers are capable of printing in both modes:

Continuous mode

In continuous mode the substrate is moved continuously. The printhead is stationary and prints while the substrate is moving.

Intermittent mode

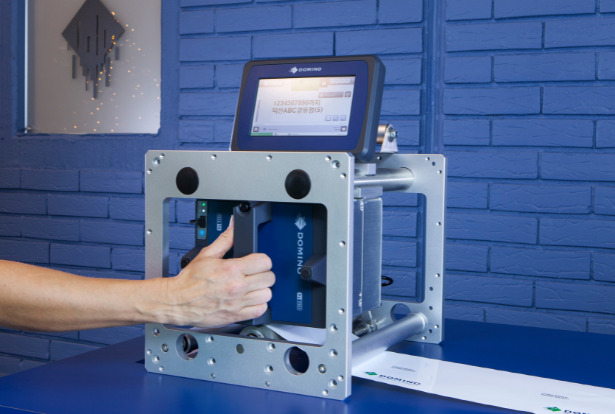

In this printing mode the substrate is moved intermittently. The printhead is moved over the substrate by the printer while the substrate is stationary.

.jpg)