Piezo Drop On Demand digital printing

K-Series

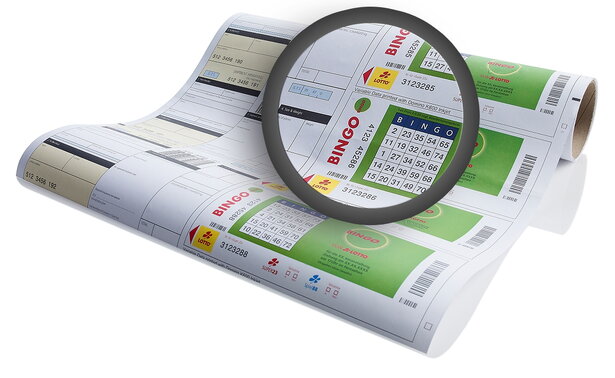

Domino K-series printers use piezo DOD technology using aqueous and/or UV inks. Drops of these inks create high-resolution text, barcodes, graphics and variable data on a wide range of coated and uncoated media, plastic cards and labels.

.jpg)