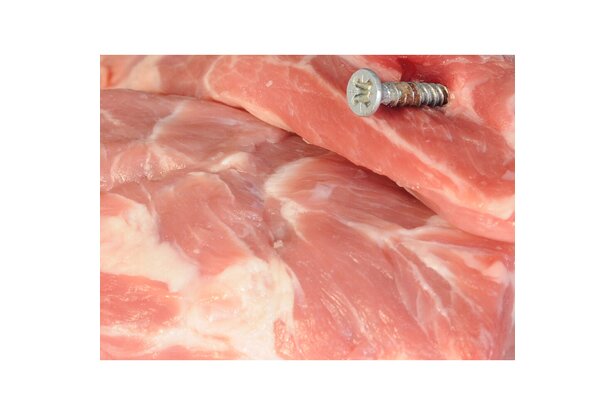

Fast, efficient disposal of contaminated products

Loma has a wide range of solutions to suit your production's requirements for rejecting contaminated product:

Stop on detect – The transport system simply stops if contamination is detected and sounds an audible alarm, allowing the operator to easily remove the contaminated product from the production line,

Air-blast – Contaminated products are ejected by a powerful blast of compressed air,

Pusher reject – A pneumatically driven rejecter redirects or ejects the product from the production line,

Retracting band reject – A system with a retracting part of the transport system that allows the contaminated product to fall into a container under the transport system,

Lockable discard bins that receive and store contaminated product – Discard bins are lockable to ensure that no detected and discarded contaminated product is returned to the production line. Reject confirmation, line blocking and bin full sensor for rejected products.